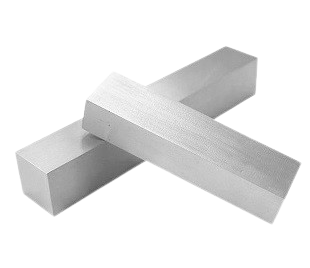

What Are Stainless Steel 316L Square Bars?

Stainless Steel 316L Square Bars are constructed using an alloy known as 316L, a low carbon variant of the popular 316 alloy that exhibits superior corrosion resistance when exposed to acidic or chloride-rich environments. They're known as low carbon due to reduced carbon content allowing easier welding processes while decreasing sensitization risk that leads to corrosion under certain circumstances. The "L" in "low carbon" denotes improved weldability as well as decreased risk.

Stainless Steel 316L Square Bars stand out with their excellent corrosion resistance, making them suitable for various demanding environments such as marine applications, chemical processing facilities and food industries. Their square shape offers additional strength and rigidity ideal for structural applications where stability and durability is of utmost importance, additionally their smooth finish facilitates easy cleaning and maintenance enhancing their suitability for hygiene applications.

Stainless Steel 316L Square Bars exhibit exceptional strength and toughness, which enables them to withstand high temperatures and pressure without deforming or experiencing structural failure, making them suitable for use in heat exchangers, pressure vessels, or equipment operating under harsh environments without deforming or failing structurally. Furthermore, its formability allows easy fabrication into various shapes or components according to specific requirements.

Automotive industries often utilize Stainless Steel 316L Square Bars in manufacturing exhaust systems, catalytic converters and other components exposed to harmful gases and chemicals. Construction sectors use them for architectural framing purposes such as structural framing or decorative elements where aesthetics and durability are important considerations. They're also widely employed for fasteners, fittings and valves used within plumbing, HVAC systems due to their resistance against corrosion or pitting in water, steam environments.

Stainless Steel 316L Square Bars have become indispensable tools in numerous industries that prioritize performance, longevity and corrosion resistance, such as aerospace and defense applications for fabricating aircraft components, missile parts and naval equipment requiring high strength corrosion resistance reliability, while in medical manufacturing of surgical instruments biocompatibility sterilization processes. Overall SS316L square bars unique versatility has made them invaluable across a range of fields where performance longevity corrosion resistance are all equally valued attributes.

Apple Steels is a renowned manufacturer and supplier of Stainless Steel 316L Square Bars in Mumbai, India. With a commitment to quality and precision, we deliver top-notch stainless steel products to meet various industrial needs. Stainless Steel 316L Square Bars are engineered with excellence, offering durability and resistance to corrosion, making them ideal for a wide range of applications. Trust us for superior quality stainless steel products that meet international standards.

Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

Forming

Most cast steel is formed by hot rolling—the slab, bloom, or billet is heated and passed through large rollers, stretching out the steel into a longer, thinner form.

Heat treatment

Heat treatment strengthens rolled stainless steel by recrystallizing the deformed microstructure. Most stainless steel is heat treated by annealing.

Descaling

A rolled piece of stainless steel acquires a layer of oxidized “mill scale,” which needs to be washed away to restore a shiny surface finish.

Cutting or Machining

Stainless steel is cut to a specified shape and size. The stainless steel can be sheared with circular knives, sawed with high-speed blades, or blanked with punches.

| Specifications | ASTM A276, A479 / ASME SA276, SA479 |

|---|---|

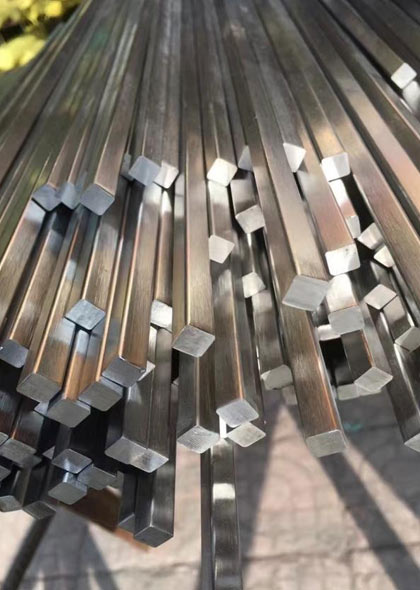

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Tolerance | h8, h9(DIN 671), h10, h11, ASTM A484, DIN 1013. |

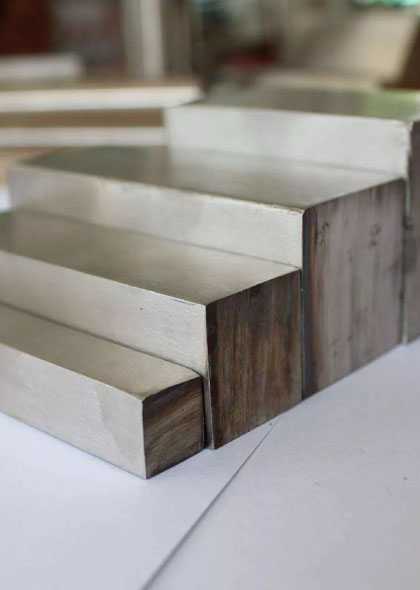

| Finish | Bright, Polish & Black. |

| Form | Square |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Other Services | Machining (CNC), Centreless Grinding (CG), Heat Treatment, Anneling, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication |

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

| SS 316L | S31603 | 1.4404 / 1.4435 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 |

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316L (S31603) |

0.03 max |

2.0 max |

0.75 max |

0.045 max |

0.03 max |

min: 16.0 max: 18.0 |

min: 2.0 max: 3.0 |

min: 10.0 max: 14.0 |

0.10 max |

| Grade | Tensile Strength ksi (min) |

Yield Strength 0.2% ksi (min) |

Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

| 316L (S31603) | 70 | 25 | 40 | 217 | 95 |

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry

Petrochemical Industry

Milk & Dairy Industry

France, Denmark, Ukraine, Netherlands, Serbia, Russia, Switzerland, Lithuania, Turkey, Portugal, Moldova, Sweden, Greece, Luxembourg, Monaco, Hungary, Czechia/Czech Republic, Latvia, United Kingdom, Norway, Ireland, Azerbaijan, Slovakia, Estonia, Cyprus, Austria, Italy, Spain, Bulgaria, Belgium, Germany, Belarus, Croatia, Finland, Romania, Poland, Liechtenstein, Malta.

Malaysia, Kuwait, Turkey, Nepal, China, Iran, Israel, Armenia, Saudi Arabia, British, Bangladesh, Singapore, Sri Lanka, Qatar, Bhutan, Jordan, Indonesia, Russia, Japan, South Korea, North Korea, Macau, Egypt, Bahrain, United Arab Emirates, Philippines, Lebanon, Vietnam, Iraq, Taiwan, Azerbaijan, Thailand, Kyrgyzstan, India, Afghanistan, Hong Kong, Maldives, Myanmar, Oman, Mongolia.

Libya, Eswatini, Seychelles, Mauritius, Madagascar, Kenya, Angola, Central African Republic, Namibia, Gambia, Botswana, Niger, Tunisia, Cameroon, Uganda, Tanzania, Senegal, Egypt, Nigeria, Zimbabwe, Zambia, Burundi, Ethiopia, Liberia, Rwanda, Burkina Faso, Morocco, Mozambique, Algeria, Mauritania, South Africa.

Canada, Nicaragua, Guyana, Guatemala, Antigua and Barbuda, Ecuador, Barbados, Dominica, Honduras, Venezuela, Brazil, Panama, Argentina, Mexico, Suriname, United States of America, Uruguay, Dominican Republic, Saint Vincent and the Grenadines, Paraguay, Trinidad and Tobago, Bahamas, Haiti, Belize, Cuba, Jamaica, Peru, Saint Lucia, Colombia, Bolivia, Costa Rica, Grenada, Chile, El Salvador.