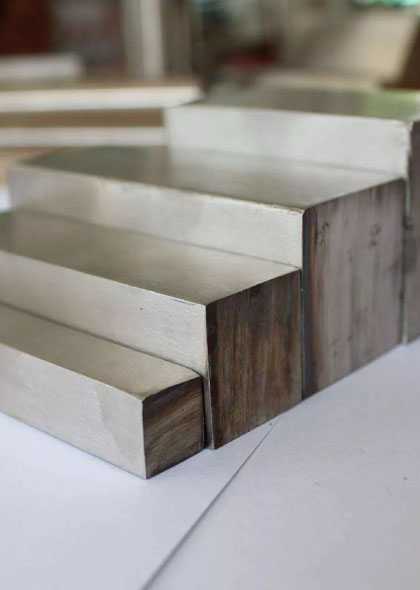

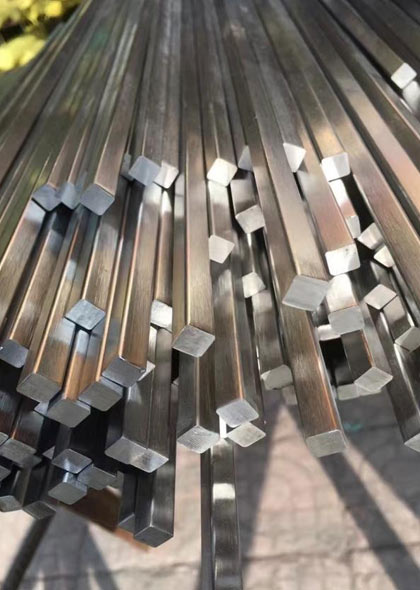

What Are Stainless Steel 316 Square Bars?

Stainless Steel 316 Square Bars are solid bars constructed with grade 316 of stainless steel that is widely recognized for its exceptional corrosion resistance and durability, typically square in shape for uniform appearance suitable for various applications. One key characteristic of stainless Steel 316 is its strong resistance to corrosion which makes it suitable for environments exposed to moisture, chemicals or extreme temperatures like marine settings or industrial settings ensuring long term reliability under difficult circumstances such as marine settings or industrial settings.

Stainless Steel 316 Square Bars offer exceptional strength and toughness, providing structural integrity and stability in demanding applications. As such, these bars make an excellent addition to construction, manufacturing and engineering projects where robust materials are essential. Their square shape facilitates easier handling and installation than other profiles as well as fabrication/assembly processes, whether used to strengthen building frameworks, machinery components or architectural features, Stainless Steel 316 Square Bars contribute greatly to overall strength and resilience of structures.

Stainless Steel 316 Square Bars boast excellent machining and welding properties that allow them to be quickly customized into various designs or configurations, facilitating simple customization or integration into different configurations and designs. Their flexibility is an attractive feature among fabricators and designers looking for materials with both functionality and aesthetic value - perfect for decorative uses like handrails, furniture pieces or interior design elements with their smooth surface finish enhancing visual appeal, while their corrosion resistance guarantees they retain their looks even under harsh environmental conditions.

Stainless Steel 316 Square Bars find widespread application across numerous industries due to their versatile combination of properties. Their uses range from construction projects and infrastructure development through manufacturing equipment manufacturing and transportation applications; making these bars essential components in structural components, fasteners, shafts and supports of machinery or equipment manufacturing plants.

Stainless Steel 316 Square Bars can be seen everywhere from architectural applications such as building facades and balustrades to signage in which durability, aesthetics and corrosion resistance are key features. Furthermore, they're used in food processing equipment production such as pharmaceutical machinery or medical devices due to their hygienic qualities that enable sterilization processes without compromise - they truly offer reliable yet versatile solutions across industries!

Apple Steels is a leading manufacturer and supplier of Stainless Steel 316 Square Bars in Mumbai, India. With a solid reputation for quality and reliability, we deliver top-notch stainless steel products to meet diverse industrial needs. Specializing in Stainless Steel 316 Square Bars, our offerings are known for their exceptional strength, durability, and corrosion resistance. Trust us for premium-grade stainless steel solutions tailored to your specifications.

Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

Forming

Most cast steel is formed by hot rolling—the slab, bloom, or billet is heated and passed through large rollers, stretching out the steel into a longer, thinner form.

Heat treatment

Heat treatment strengthens rolled stainless steel by recrystallizing the deformed microstructure. Most stainless steel is heat treated by annealing.

Descaling

A rolled piece of stainless steel acquires a layer of oxidized “mill scale,” which needs to be washed away to restore a shiny surface finish.

Cutting or Machining

Stainless steel is cut to a specified shape and size. The stainless steel can be sheared with circular knives, sawed with high-speed blades, or blanked with punches.

| Specifications | ASTM A276, A479 / ASME SA276, SA479 |

|---|---|

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Tolerance | h8, h9(DIN 671), h10, h11, ASTM A484, DIN 1013. |

| Finish | Bright, Polish & Black. |

| Form | Square |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Other Services | Machining (CNC), Centreless Grinding (CG), Heat Treatment, Anneling, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication |

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

| SS 316 | S31600 | 1.4401 / 1.4436 | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | - |

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 (S31600) |

0.08 max |

2.0 max |

0.75 max |

0.045 max |

0.03 max |

min: 16.0 max: 18.0 |

min: 2.0 max: 3.0 |

min: 10.0 max: 14.0 |

0.10 max |

| Grade | Density | Melting Point | Tensilee Strength | Yield Strength (0.2%Offset) | Elongation |

| 316 (S31600) | 75 | 30 | 40 | 217 | 95 |

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry

Petrochemical Industry

Milk & Dairy Industry

Estonia, Belarus, Germany, Azerbaijan, Luxembourg, Poland, Denmark, Ireland, France, Ukraine, Belgium, Hungary, Austria, Finland, Czechia/Czech Republic, Norway, Switzerland, Cyprus, Lithuania, Malta, Moldova, Croatia, Sweden, Liechtenstein, Latvia, Turkey, Monaco, United Kingdom, Portugal, Greece, Serbia, Bulgaria, Spain, Netherlands, Italy, Romania, Slovakia, Russia.

Singapore, North Korea, Qatar, Myanmar, Lebanon, Iran, Turkey, Israel, United Arab Emirates, Macau, Bahrain, India, Thailand, Bangladesh, Nepal, Kuwait, Philippines, Afghanistan, Bhutan, South Korea, Oman, Saudi Arabia, Taiwan, Vietnam, China, Hong Kong, Sri Lanka, Mongolia, Russia, Indonesia, Azerbaijan, Armenia, Jordan, British, Maldives, Japan, Egypt, Kyrgyzstan, Malaysia, Iraq.

Burkina Faso, Nigeria, South Africa, Central African Republic, Algeria, Zimbabwe, Senegal, Kenya, Zambia, Egypt, Ethiopia, Rwanda, Tanzania, Morocco, Madagascar, Seychelles, Libya, Cameroon, Mauritius, Niger, Angola, Eswatini, Liberia, Gambia, Namibia, Tunisia, Mauritania, Burundi, Uganda, Botswana, Mozambique.

Jamaica, Paraguay, Belize, Dominica, Venezuela, Colombia, Brazil, Cuba, El Salvador, Barbados, Mexico, Nicaragua, Peru, Guyana, Costa Rica, Ecuador, Bahamas, Argentina, Honduras, Uruguay, Suriname, Trinidad and Tobago, Chile, Saint Vincent and the Grenadines, Dominican Republic, Grenada, Canada, Saint Lucia, Guatemala, United States of America, Antigua and Barbuda, Bolivia, Haiti, Panama.