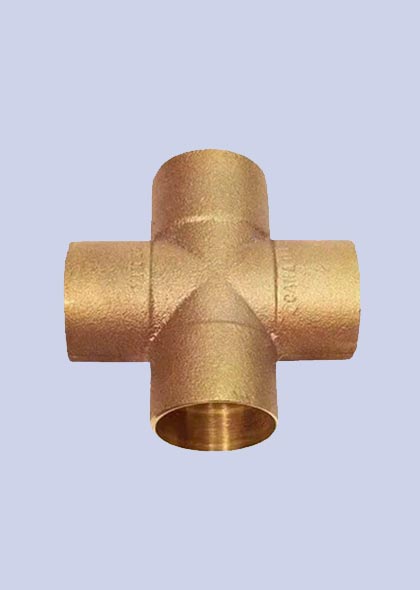

Cupro Nickel fittings are components made from Cupro Nickel alloy containing copper and nickel with trace amounts of iron or manganese as additions, finding wide application in many industries due to its combination of properties.

Cupro Nickel fittings feature various advantages, including high strength and excellent resistance to corrosion, erosion and biofouling. In addition, these fittings resist stress corrosion cracking while having good thermal conductivity and thermal balancing qualities - perfect for demanding applications that demand high temperature resistance and pressure resistance.

Cupro Nickel fittings stand out for being highly machinable despite their inherent toughness, enabling specialized fittings tailored specifically to individual specifications - which makes them versatile enough to suit various manufacturing processes and applications.

Cupro Nickel fittings are well known for their remarkable corrosion resistance in marine and industrial settings, due to the alloy's composition which forms an oxide film layer protecting its surface, protecting from further deterioration. As a result, Cupro Nickel fittings typically last long in demanding environments making them an economical solution that stands up well when dealing with critical applications.

Cupro Nickel fittings stand out due to their weldability. Welded using techniques such as gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW), they facilitate ease of installation while simultaneously fabricating complex structures ensuring seamless integration into systems or pipelines.

Cupro Nickel fittings find widespread application across industries including shipbuilding, offshore oil and gas exploration and production, chemical processing plants, desalination facilities and power generation. Their corrosion resistant surface finishes make them suitable for heat exchangers, condensers, valves and other critical components in which corrosion resistance, durability and reliability play key roles.

Cupro Nickel fittings find applications across a range of fields, including marine piping systems where their resistance to seawater corrosion helps preserve integrity over extended periods. Furthermore, power plants utilizing Cupro Nickel fittings as heat exchangers or condensers benefit greatly from its thermal conductivity and corrosion resistance, and chemical processing plants where their exposure to chemical acids helps ensure safe operation and reliable results.

Apple Steels is a renowned manufacturer and supplier of high-quality Cupro Nickel fittings in Mumbai, India. Specializing in corrosion-resistant alloys, we offers a comprehensive range of Cupro Nickel fittings designed for various industrial applications. With a reputation for reliability and excellence, Apple Steels delivers top-notch products crafted to meet stringent quality standards.

Forging

Making method of forged fittings,using forging machine bevels the pipe end or extension, reduce the outside diameter.

Rolling Wheel

Butt weld fittings, putting the core in the pipe. Then pushing the external by roller and processing the rim.

Stamping

Using tapered core to expand the pipe end to the required size and shape in the punching machine.

Bending

For making elbow and bend fittings. There are three commonly methods. One is stretching , another is stamping , the third is roller , there are 3-4 rollers.

Bulging

A rubber is placed in the tube and the top with a punch compression, then the pipe is bulged forming; Another method is hydraulic bulging forming.

| Specifications | ASTM B466 / ASME SB466 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Type | DN15-DN1200 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Duplex Steel Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 Duplex Steel Buttweld Fitting |

| Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D,

7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Connection | Welding |

| Manufacturing process | Forge, Cast, Push, Press, etc. |

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry

Petrochemical Industry

Milk & Dairy Industry

Austria, Azerbaijan, Belarus, Belgium, Bulgaria, Croatia, Cyprus, Czechia/Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Malta, Moldova, Monaco, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom.

Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, British, China, Egypt, Hong Kong, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kuwait, Kyrgyzstan, Lebanon, Macau, Malaysia, Maldives, Mongolia, Myanmar, Nepal, North Korea, Oman, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, Turkey, United Arab Emirates, Vietnam.

Algeria, Angola, Botswana, Burkina Faso, Burundi, Cameroon, Central African Republic, Egypt, Eswatini, Ethiopia, Gambia, Kenya, Liberia, Libya, Madagascar, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Senegal, Seychelles, South Africa, Tanzania, Tunisia, Uganda, Zambia, Zimbabwe.

Antigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela.