17-4Ph H1025 Condition Round Bars are a specific type of stainless steel round bars heat treated to deliver maximum strength, corrosion resistance, and toughness. Their name refers to their composition: approximately 17% chromium to 4% nickel with trace amounts of copper and other elements added for additional reinforcement and precipitation hardening for enhanced mechanical properties.

17-4Ph H1025 Condition Round Bars stand out due to their exceptional strength. Exhibiting high tensile and yield strengths, making them suitable for applications where robustness and durability is key. Furthermore, their corrosion-resistance makes them suitable for marine environments, chemical processing equipment and offshore oil and gas platforms.

H1025 refers to an advanced heat treatment process applied to materials. Under this condition, round bars are solution annealed before rapidly cooling back down to room temperature before being aged at relatively low temperatures to achieve specific mechanical properties and achieve strength/toughness balance suited for various demanding applications.

17-4Ph H1025 Condition Round Bars have many diverse uses due to their combination of properties, from aerospace fittings and landing gear parts, engine components and engine accessories requiring high strength and corrosion resistance, manufacturing machinery components molds tooling as wear resistance dimensional stability properties make useable, medical uses include surgical instruments as implants thanks to biocompatibility properties or as bioactive implants with superior corrosion resistance properties.

Apple Steels is a leading manufacturer and supplier of 17-4Ph H1025 Condition Round Bars in Mumbai, India. Driven by excellence and dedication to customer satisfaction, our round bars meet stringent industry standards while still meeting rigorous specifications. Thanks to cutting-edge technology we deliver precision engineering with impeccable performance across diverse applications, known for durability corrosion resistance high tensile strength our 17-4Ph H1025 Condition Round Bars are trusted globally by industries. At Apple Steels our top priority is customer service backed up with reliable products backed with superior support backed up by exceptional service coupled with fast deliveries - just another way we set ourselves apart!

Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

Forming

Most cast steel is formed by hot rolling—the slab, bloom, or billet is heated and passed through large rollers, stretching out the steel into a longer, thinner form.

Heat treatment

Heat treatment strengthens rolled stainless steel by recrystallizing the deformed microstructure. Most stainless steel is heat treated by annealing.

Descaling

A rolled piece of stainless steel acquires a layer of oxidized “mill scale,” which needs to be washed away to restore a shiny surface finish.

Cutting or Machining

Stainless steel is cut to a specified shape and size. The stainless steel can be sheared with circular knives, sawed with high-speed blades, or blanked with punches.

| Specification | ASTM A564 / ASME SA564 |

| Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars | Outside Diameter in the range of 4mm to 100mm |

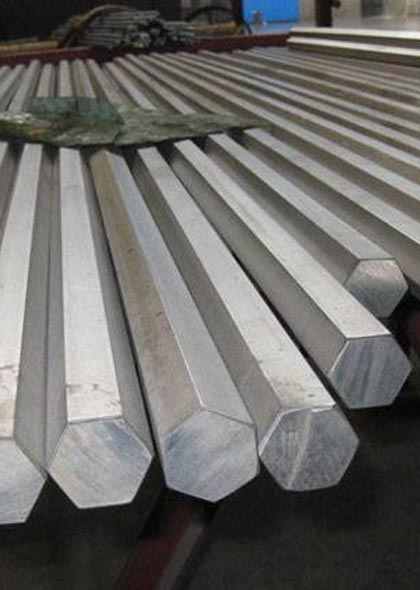

| Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | 33 x 30mm to 295 x 1066mm |

SS 17-4PH H1025 Round Bar

Stainless Steel 17-4PH H1025 Square Bar

Stainless Steel 17-4PH H1025 Hollow Bar

Stainless Steel 17-4PH H1025 Hex Bar

Stainless Steel 17-4PH H1025 Bright Bar

17-4 PH H1025 Stainless Steel Rods

17-4 PH H1025 Stainless Steel Bar

AISI 17-4 PH H1025 Hexagon Bars

AMS 5643 17-4 PH H1025 Polish Bars

| Grade | C | P | Si | Ni | Cu | Fe | Mn | S | Cr | Cb+Ta |

| SS 17-4 PH | 0.07 | 0.04 | 1.0 max | 3.0 – 5.0 | 3.0 – 5.0 | Bal | 1.0 max | 0.03 | 15.0 – 17.5 | 5 X C / 0.45 |

|

Condition

|

Ultimate Tensile

Strength (PSI) |

0.2% Yield

Strength (PSI) |

Elongation

(% in 2in.) |

Reduction Of

Area (%) |

Hardness

Brinell |

Hardness

Rockwell |

|---|---|---|---|---|---|---|

|

H900

|

190,000

|

170,000

|

10

|

40

|

388

|

C40

|

|

H1025

|

155,000

|

145,000

|

12

|

45

|

331

|

C35

|

|

H1075

|

145,000

|

125,000

|

13

|

45

|

311

|

C32

|

|

H1150

|

135,000

|

105,000

|

16

|

50

|

277

|

C28

|

|

H1150-M

|

115,000

|

75,000

|

18

|

55

|

255

|

C24

|

|

H1150-D

|

125,000

|

105,000

|

16

|

50

|

255 min-

311 max |

C24-33

|

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry

Petrochemical Industry

Milk & Dairy Industry

Austria, Azerbaijan, Belarus, Belgium, Bulgaria, Croatia, Cyprus, Czechia/Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Malta, Moldova, Monaco, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom.

Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, British, China, Egypt, Hong Kong, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kuwait, Kyrgyzstan, Lebanon, Macau, Malaysia, Maldives, Mongolia, Myanmar, Nepal, North Korea, Oman, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, Turkey, United Arab Emirates, Vietnam.

Algeria, Angola, Botswana, Burkina Faso, Burundi, Cameroon, Central African Republic, Egypt, Eswatini, Ethiopia, Gambia, Kenya, Liberia, Libya, Madagascar, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Senegal, Seychelles, South Africa, Tanzania, Tunisia, Uganda, Zambia, Zimbabwe.

Antigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela.