17-4Ph H1000 Condition Round Bars refer to an exceptional type of stainless steel alloy known for its outstanding strength, corrosion resistance and versatility. Their "17-4Ph" designation refers to their composition containing approximately 17% chromium and 4% nickel as well as other elements like copper and niobium, their "H1000 Condition" means they have undergone heat-treatment to reach high strength levels with typically reaching 1000 MPa tensile strength ratings.

17-4Ph H1000 Condition Round Bars stand out for their extraordinary strength-to-weight ratio, making them suitable for applications requiring both durability and reduced weight. Their remarkable ratio makes 17-4Ph H1000 Condition Round Bars ideal for aerospace components like aircraft structural parts or engine components where strength, corrosion resistance, and high strength requirements must all be fulfilled simultaneously.

Additionally, round bars find widespread application in marine industry applications due to their resistance against saltwater corrosion and mechanical strength, perfect for off-shore platforms, marine shafts and propeller shafts as well as under water applications due to harsh environmental conditions.

17-4Ph H1000 Condition Round Bars are widely utilized throughout the oil and gas sector in components like valves, pumps and drilling equipment where their durability under demanding operating conditions, including high-pressure and corrosive environments.

Due to their corrosion resistance and ease of fabrication, round bars are used in manufacturing equipment used for chemical processing vessels, pharmaceutical machinery and food processing applications.

Apple Steels is a leading manufacturer and supplier of 17-4Ph H1000 Condition Round Bars in Mumbai, India. Proud of our reputation of meeting stringent industry standards with top-quality products like our round bars manufactured to guarantee exceptional strength, durability, corrosion resistance, making them suitable for applications across industries and applications across various fields. Backed by state-of-the-art manufacturing facilities staffed with skilled professionals we're committed to offering unrivaled quality and service worldwide for customers worldwide.

Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

Forming

Most cast steel is formed by hot rolling—the slab, bloom, or billet is heated and passed through large rollers, stretching out the steel into a longer, thinner form.

Heat treatment

Heat treatment strengthens rolled stainless steel by recrystallizing the deformed microstructure. Most stainless steel is heat treated by annealing.

Descaling

A rolled piece of stainless steel acquires a layer of oxidized “mill scale,” which needs to be washed away to restore a shiny surface finish.

Cutting or Machining

Stainless steel is cut to a specified shape and size. The stainless steel can be sheared with circular knives, sawed with high-speed blades, or blanked with punches.

| Specification | ASTM A564 / ASME SA564 |

| Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars | Outside Diameter in the range of 4mm to 100mm |

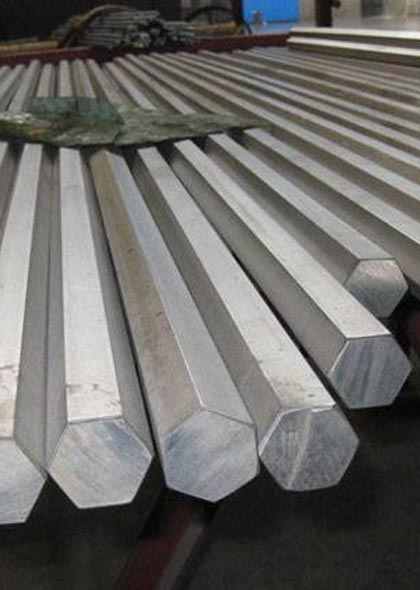

| Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | 33 x 30mm to 295 x 1066mm |

SS 17-4PH H1000 Round Bar

Stainless Steel 17-4PH H1000 Square Bar

Stainless Steel 17-4PH H1000 Hollow Bar

Stainless Steel 17-4PH H1000 Hex Bar

Stainless Steel 17-4PH H1000 Bright Bar

17-4 PH H1000 Stainless Steel Rods

17-4 PH H1000 Stainless Steel Bar

AISI 17-4 PH H1000 Hexagon Bars

AMS 5643 17-4 PH H1000 Polish Bars

| Grade | C | P | Si | Ni | Cu | Fe | Mn | S | Cr | Cb+Ta |

| SS 17-4 PH | 0.07 | 0.04 | 1.0 max | 3.0 – 5.0 | 3.0 – 5.0 | Bal | 1.0 max | 0.03 | 15.0 – 17.5 | 5 X C / 0.45 |

|

Condition

|

Ultimate Tensile

Strength (PSI) |

0.2% Yield

Strength (PSI) |

Elongation

(% in 2in.) |

Reduction Of

Area (%) |

Hardness

Brinell |

Hardness

Rockwell |

|---|---|---|---|---|---|---|

|

H900

|

190,000

|

170,000

|

10

|

40

|

388

|

C40

|

|

H1025

|

155,000

|

145,000

|

12

|

45

|

331

|

C35

|

|

H1075

|

145,000

|

125,000

|

13

|

45

|

311

|

C32

|

|

H1150

|

135,000

|

105,000

|

16

|

50

|

277

|

C28

|

|

H1150-M

|

115,000

|

75,000

|

18

|

55

|

255

|

C24

|

|

H1150-D

|

125,000

|

105,000

|

16

|

50

|

255 min-

311 max |

C24-33

|

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry

Petrochemical Industry

Milk & Dairy Industry

Austria, Azerbaijan, Belarus, Belgium, Bulgaria, Croatia, Cyprus, Czechia/Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Malta, Moldova, Monaco, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom.

Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, British, China, Egypt, Hong Kong, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kuwait, Kyrgyzstan, Lebanon, Macau, Malaysia, Maldives, Mongolia, Myanmar, Nepal, North Korea, Oman, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, Turkey, United Arab Emirates, Vietnam.

Algeria, Angola, Botswana, Burkina Faso, Burundi, Cameroon, Central African Republic, Egypt, Eswatini, Ethiopia, Gambia, Kenya, Liberia, Libya, Madagascar, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Senegal, Seychelles, South Africa, Tanzania, Tunisia, Uganda, Zambia, Zimbabwe.

Antigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela.